Uploading code wirelessly to Arduino Mega

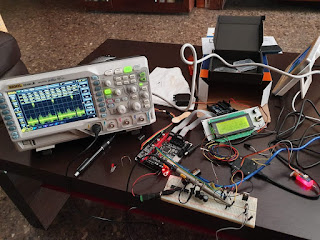

Given the same thing worked ok using an Arduino UNO form-factor board with both an AVR 328p and an ESP8266, I was expecting not much trouble getting the same thing to work for a similar board in the Arduino Mega format. Oh boy, I was wrong! The hardware modification part was easy: Find the diode whose cathode is connected to the RESET pin and remove it from the board. ( Board schematic ) I used GPIO12 as the ESP8266 pin to be used to reset the AVR processor (key for a remote upload). But once the hardware was working, it became obvious the software side of things was just not working. I could see no communication was ever successful between the ATMega2560 and avrdude program. Reset generation was not a problem as it was clear remote reset was working ok. Perhaps timing? Let us read about possible issues on github. It turns out this is old news, as ESP-Link is playing a trick to detect the attempt of a firmware upload so it can reset the AVR chip then. That detection was...