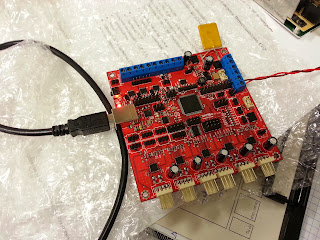

Teaching Rambo how to print

I could not resist the temptation and I bought a discounted RAMBo board a while ago. Today each attempt to upload some code ended up in a list of messages like the ones below: avrdude: stk500v2_ReceiveMessage(): timeout avrdude: stk500v2_getsync(): timeout communicating with programmer First idea was that the board might not contain a bootloader, but after using my recently acquired ICSP programmer and obtaining a dump of the ATMega 2560 from the board I could see it was exactly the same as the one from a regular Arduino Mega board. As it is a new board, there is a chance of being a DOA. But I was surprised that no LED was lit when I connected the USB port. However, I could see one of the LEDs from the serial port (I guessed this is what they were) blinking when I was trying (unsuccessfully) to upload a sketch to the board. I realize that while I dumped the flash memory of the Mega, more LEDs were lit. It then hit me that maybe the only problem was that the board (the v...