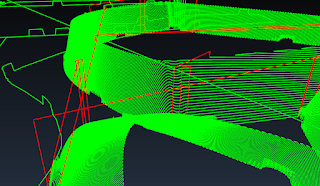

New iPhone app too

A few weeks ago I mentioned a new Android app was available to assist during the assembly of projects made of blocks of stacked layers of material. That will not be complete with a similar app for those of you own Apple cellphones and iPad tablets. For the moment the app is available for iOS 12 devices . Supporting older versions has not been a priority as we did not want development to lag behind but we might venture there if we get enough requests. As with the Android app, this version is free too. A sample model is embedded so you can see how it works (go to the gear menu).